CLICK ON THE CATEGORY OF GRINDERS YOU ARE LOOKING FOR!

NEW & USED GRINDERS

Are You Looking For A Good New & Used Grinder Machine?

We have dozens of Grinders for sale & in stock.

-

USED BELT FOR SALE CURRENTLY IN STOCK

BRAND NEW BELT FOR SALE CURRENTLY IN STOCK

-

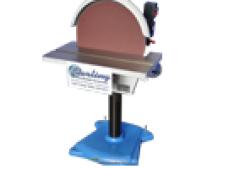

USED DISC FOR SALE CURRENTLY IN STOCK

BRAND NEW DISC FOR SALE CURRENTLY IN STOCK

-

USED GRINDERS, CYLINDRICAL PLAIN (ANGLE) & UNIVERSAL FOR SALE CURRENTLY IN STOCK

BRAND NEW GRINDERS, CYLINDRICAL PLAIN (ANGLE) & UNIVERSAL FOR SALE CURRENTLY IN STOCK

-

USED PEDESTAL TYPE & POLISHERS FOR SALE CURRENTLY IN STOCK

-

USED SURFACE, RECIPROCATING (HORIZONTAL SPINDLE), N/C & CNC FOR SALE CURRENTLY IN STOCK

BRAND NEW SURFACE, RECIPROCATING (HORIZONTAL SPINDLE), N/C & CNC FOR SALE CURRENTLY IN STOCK

-

USED TOOL & CUTTER FOR SALE CURRENTLY IN STOCK

BRAND NEW TOOL & CUTTER FOR SALE CURRENTLY IN STOCK

A grinding machine is a machine tool used for producing very fine finishes or making very light cuts, using an abrasive wheel as the cutting device. This wheel can be made up of various sizes and types of stones, diamonds or of inorganic materials. There are many different types of grinders, all set up for different applications.

We Buy & Sell All Types Of Metal Grinding Machines Such As:

- Surface Grinders- Brown & Sharpe, Kent, Okamoto, Acer, Acra, Chevalier

- Tool & Cutter Grinders- Cincinnati, K.O. Lee, DoAll

- Disc Grinders- Apex

- Die Grinders- Amada, Wilson Tools

- Vertical Rotary Grinders- Blanchards

- Drill Grinder- Giddings & Lewis

- Belt Grinders- Timesaver, AEM, Ramco

- Single Lip Grinder- Deckels